So… I may owe some level of explanation for waiting a year between my last post and this one…

Maybe.

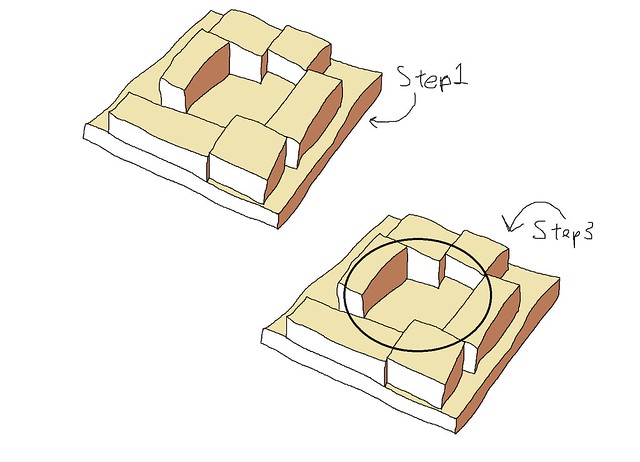

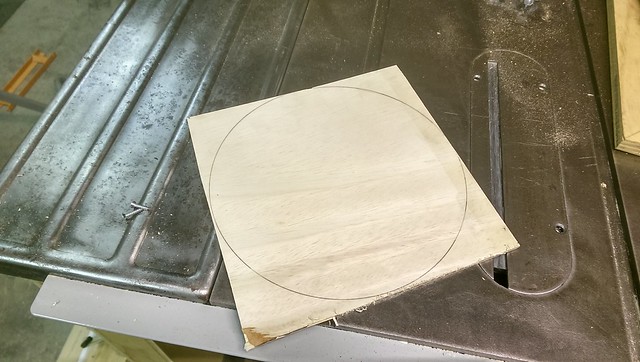

I made a housing for my impeller by arranging several blocks of red oak on a piece of plywood and then tracing the perimeter of my impeller onto the blocks of wood.

I appear to have lost any photographic record of this step, so please view the following for reference:

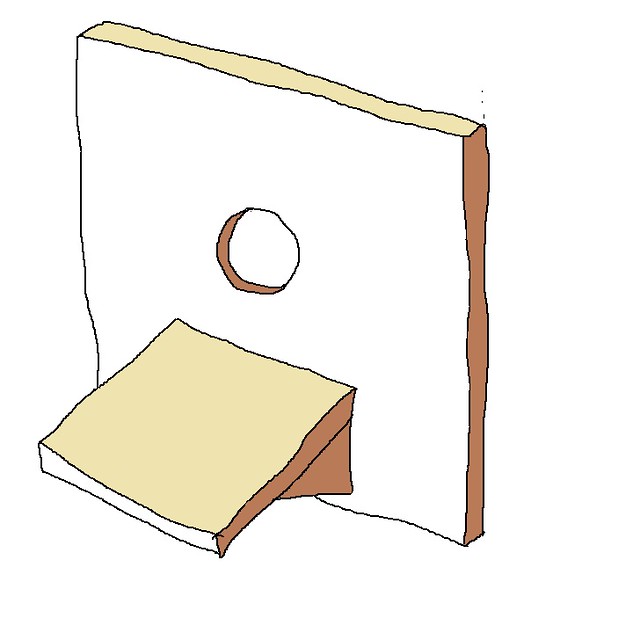

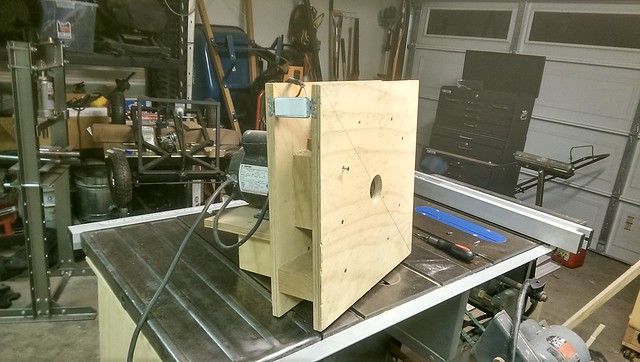

I then cut this line on each piece using my bandsaw. I rearranged the cut blocks so that they made the correct shape and then screwed them on to the piece of plywood. i also smeared from Bond-O on to the inside circumference to smooth out inconsistencies and plug any gaps. I drilled a large hole into the center of the plywood to pass the motor through and made a little platform for the motor to rest on.

I then cut this line on each piece using my bandsaw. I rearranged the cut blocks so that they made the correct shape and then screwed them on to the piece of plywood. i also smeared from Bond-O on to the inside circumference to smooth out inconsistencies and plug any gaps. I drilled a large hole into the center of the plywood to pass the motor through and made a little platform for the motor to rest on.

After cutting a hole in the front piece, I slapped everything together for another test. It Sucked. But not as much as I hoped. I sat and pondered. and then got distracted. For a year. At some point during that year, I realized why my dust collected only sucked a little, but still waited a number of months before doing anything about it. Let’s play a fun game: Can you figure out what was wrong with my dust collector?

=== SPOILER ALERT! ===

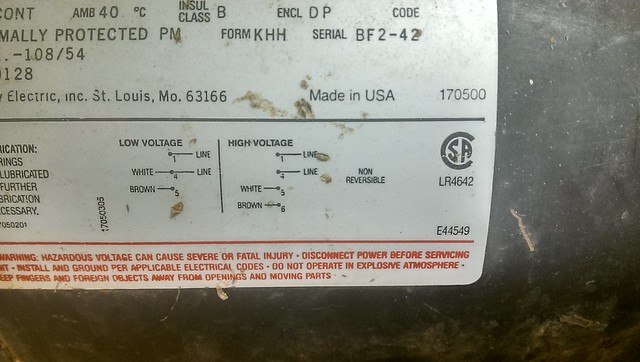

The impeller is spinning the wrong way. To make matters worse, the motor is unambiguously non reversible.

So I immediately (when I felt like it) got to work. I decided to solve the problem by moving the motor around to the “front” of the assembly. This also meant that I needed to keep the impeller in the same orientation relative to the housing, and so I needed to turn the back of the impeller into the front and re-mount it on the motor shaft:

So I immediately (when I felt like it) got to work. I decided to solve the problem by moving the motor around to the “front” of the assembly. This also meant that I needed to keep the impeller in the same orientation relative to the housing, and so I needed to turn the back of the impeller into the front and re-mount it on the motor shaft:

Easy peasy. I powered it up for a test run, and promptly woke my son up (I have a son, he’s almost 2 and he was asleep).

Easy peasy. I powered it up for a test run, and promptly woke my son up (I have a son, he’s almost 2 and he was asleep).

Needless to say, it was louder than I hoped.

I had recalled Wandel doing some testing around making his impeller design quieter and subsequently much, much louder to make an air raid siren. So I scoured his website and failed to find the article I was looking for, but did find a comment of his on someone else’s dust collector design where he noted that “the smaller the gap between the impeller and the housing, the louder it will be.”

So I shaved 1/4″ off the perimeter of my impeller using my bandsaw and put everything back together.

Then I waited until my son was asleep again (for maximum effect) and tested it again.

This time it REALLY sucked. And it did so very quietly. Almost Dust-Sniper quiet!

And so I set in a corner of my garage until I get time to mount and duct it.

Next June is looking promising…